A key step in making high performance heat transfers in screenprinting or hybrid systems is the usage

of a suitable adhesive, which will ensure qualitative adhesion between the transfer applied via heat-press

and the desired garment or substrate. The choice of the adhesive depends on desired final application features and on temperatures substrates can tolerate during heat-pressing. There are two types of adhesives compatible with the DST technology: powder and printable/liquid adhesive. Each of these have their unique characteristics and benefits, which we will explore in the paragraphs below.

Powder adhesive

What is powder adhesive?

DST Soft Powder, DST Low Melt Powder XF and DST SP High Grade are adhesives in powder form, ground to a particle size between 80-200𝝁. They are either thermoplastic polyurethane (TPU), co-polyester (CoPES), or co-polyamide (CoPA) based powders, the later specifically with excellent durability up to 90°C wash cycle.

Properties of powder adhesive

Powder adhesives deliver transfers that are flexible and soft. However, if stretched too much, the resulting transfer is likely to crack. They can be applied at lower temperatures (100-130°C) than printable adhesives. Suitable substrates for powder adhesive can be polypropylene, cotton, polyester, wood, leather, jute, or cardboard.

Application of powder adhesive

The powder adhesive is used as a scatter coat application onto the wet white ink before the ink dries and makes a film. The powder covers the white ink of the transfer, penetrating slightly the ink film, but doesn’t remain on the release liner area not covered by the ink. After this step, the sheets are dried in an oven for approx. 90 sec before the heat transfer is ready to be applied on the garment.

Printable or Liquid adhesive

What is printable or liquid adhesive?

Printable or liquid adhesives are liquid film-forming adhesive containing TPU as base polymer. They can be water- or plastisol-based, and phthalate-free. The current DST portfolio includes the following printable adhesives: DST PLAD Adhesive extra durable, DST WB Adhesive and DST WB Adhesive extra durable.

Properties of printable or liquid adhesive

Liquid adhesives provide transfers that are highly flexible and have great stretchability due to shape memory feature of TPU. Compared to powder adhesives, they must be applied at higher temperatures (>160°C) to ensure perfect bondability. Suitable garments for such applications could be cotton, polyester, wood, or jute.

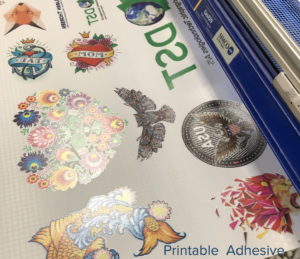

Application of printable or liquid adhesive

Printable adhesive is printed on the white ink after the ink dries in the oven for 90 sec. It is applied via a screen-printing method, with a specific screen/mesh and a ‘squeegee’ just like for the white ink in the previous step. The use of printable adhesive requires an additional screen. The liner is then dried into the oven for 90 sec.

Comparative table

The table below provides a quick overview of the main differences between powder and printable adhesives:

Powder adhesive | Plastisol printable adhesive | Water-based printable adhesive | |

|---|---|---|---|

Benefits | Soft, flexible, solid transfer, application at lower temperatures (100-130°C) | High stretchability, shape memory, application at higher temperatures (>160°C) | High stretchability, shape memory, application at higher temperatures (>160°C) |

Transfer quality | Particle size can be changed to adapt to the garment | Best image contour cut & contrast | Best image contour cut & contrast More uniform film |

Application versatility | Polypropylene, cotton, polyester, wood, leather, jute, cardboard | Cotton, polyester, wood, jute | Cotton, polyester, wood, jute |

Sustainability component | Recyclable, no waste Oeko-Tex Standard 100 compatible | Phthalate-free Eco-Passport | Halogen-free Eco-Passport |

Suitable for | Any type of transfer Any number of transfers | Any type of transfer Medium to high number of transfers | High-end transfer Medium to high number of transfers Full water-based system |

About DST

Digital Serigraphic Technologies A/S (DST A/S) is a majority-owned affiliate of the Bjørn Thorsen group (BTG). The company was established in March 2020. Today, the DST commercial portfolio consists of four product categories: Release liners, Inks, Adhesives and Special Additives.